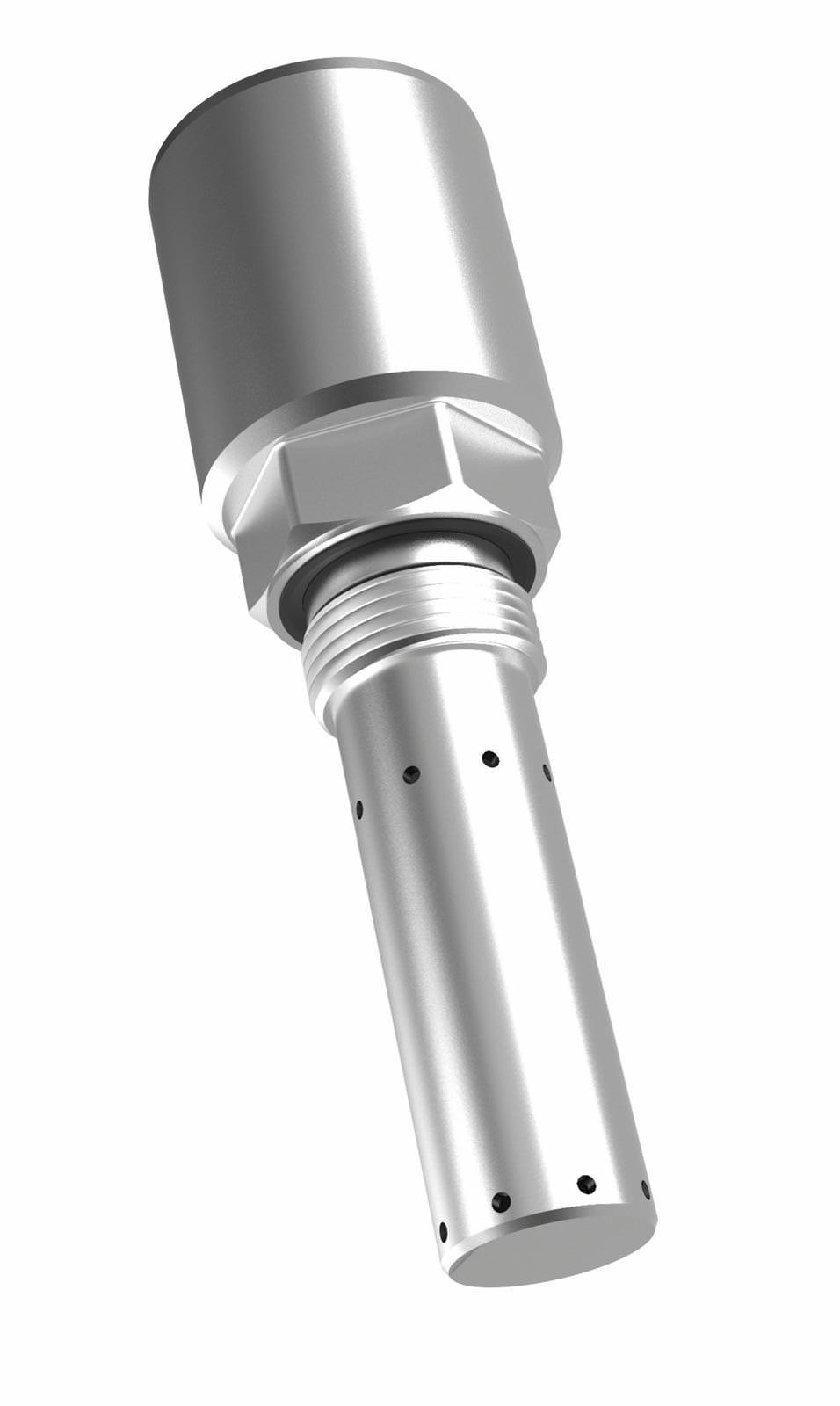

SFS Viscosity Sensor

SFS Viscosity Sensor for determination of the viscosity, relative dielectric number and temperature in hydraulic and lubricating oils. SFS Viscosity Sensor is a screw-in sensor and immersion sensor respectively and is designed for continuous monitoring of the oil condition.