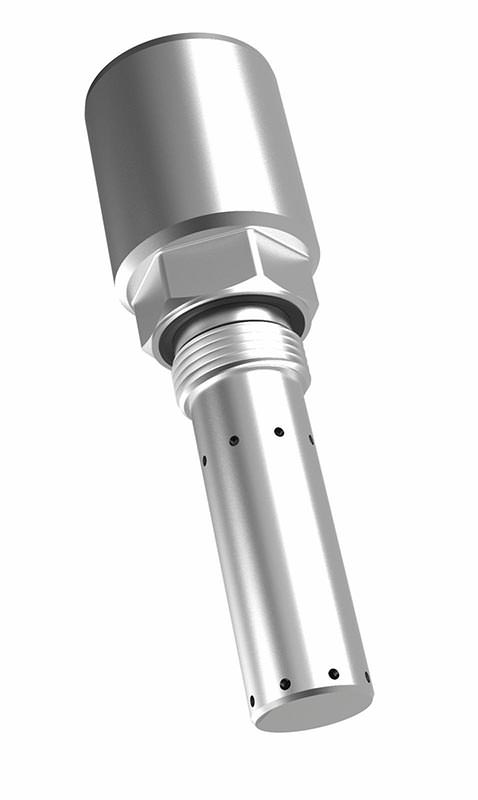

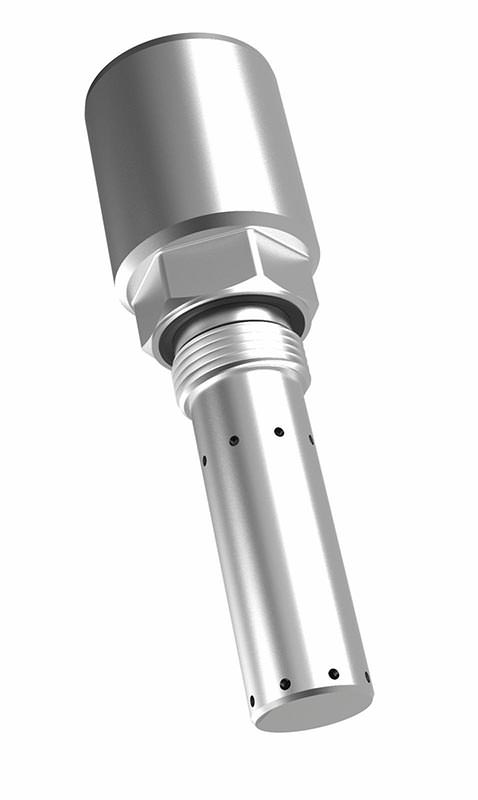

SFS H2O+

Stationary screw-in sensor for continuous determination of the oil condition, humidity and temperature in hydraulic and lubricating oils.

A Platform for Intelligent Condition Monitoring.

Stationary screw-in sensor for continuous determination of the oil condition, humidity and temperature in hydraulic and lubricating oils.

Measurement of changes in hydraulic fluids and lubricants. Data is continuously documented evaluated and stored. In that way deterioration and changes in the oil (e.g. water inleakage, oil change, …) can be indicated. Through this, damage can be recognized or completely avoided at an early stage. This offers the opportunity to prevent machine failures as well as to prolong maintenance and oil change intervals by means of appropriate measures. Furthermore, by monitoring the lubricant, correctly performed maintenance work and the use of the required lubricant quality may be documented.

The sensor records the following physical oil characteristics as well as its periodic change: Temperature, relative oil humidity and water activity resp., relative dielectric number (relative permittivity) and conductivity of the fluid. As especially the conductivity and the relative dielectric number show a strong connection to the temperature, next to the characteristic values at current temperature the sensor also sends the data at reference temperature (40 °C / 104 °F). The sensor is able to evaluate condition changes automatically.

The sensor is provided with a G¾ thread and can be integrated in the tank. The communication with the sensor either takes place over a serial RS 232 interface, two analogue outputs (4 … 20 mA) or CANopen. In order to also enable a long-term record of data up to half a year, the sensor is provided with an internal data storage unit.